Manufacturing

Your manufacturing business must be set up properly to optimize space and workflow. Let our manufacturing experts design a solution for you that considers all the critical components of your business and maximizes your productivity.

The Right Design

Maximizes Output

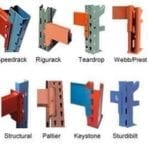

- – Raw Material: The manufacturing process frequently requires space efficient and practical storage of raw materials. This requirement is defined by the products and velocity of the items into the manufacturing stream.

- – WIP: Work in process requirements have become increasingly complex as product serialization, labeling and real-time manufacturing data capture is utilized. This requirement can include the storage, staging, and transportation of components through the manufacturing process.

- – POU: Point of use storage is critical to the efficiency of manufacturing and assembly systems. The design, sizing and flexibility are primary considerations in their design.

- – Work Simplification: Inefficient and cumbersome work envelopes contribute to lost productivity. Work simplification addresses lifting and positioning of components, cellular flow, and process efficiency in the manufacturing environment.

- – Space Planning: Constantly changing product mix and seasonality exert pressure on manufacturing facilities available space. Space planning provides a thoughtful pre-planned strategy for managing space demands in the operation now, and in the future.

let us design your system today

We have full turnkey design capabilities to show you how to feed a sort system properly, achieve the rates you desire, and manage the system with state of art SCADA software. Our SCADA software can be implemented to monitor from any device anywhere in the world!

See why Multi-Billion Dollar companies like FedEX, Nebraska Furniture Mart, Chewy.com, S&S Activewear, Mouser Electronics, RTIC, KGP, and multiple others trust the engineering and partnership of Precision Warehouse Design for their current and ongoing Conveyor Sortation and Design needs!