Warehouse Software Systems

Precision Warehouse Design understands how to integrate Industrial software solutions to interact with your warehouse.

We use a variety of Solutions. Our In-house solution is PrecisonWareh360 Powered by Ignition by Inductive Automation.

If your number one goal is to enjoy short- and long-term growth as a long-running and efficient warehouse, you need to invest in warehouse software systems to get a foot ahead of the competition. We can’t even explain how many warehouses nationwide still do everything manually when better options exist.

A warehouse software system, sometimes referred to as a warehouse management system, benefits operational logistics by bolstering efficiency for both the various conveyor systems and your labor force.

But where to begin? There are countless options for warehouse software, so let’s start by discussing a few worthwhile and cost-effective solutions Precision Warehouse Design works with daily.

A Broad Range

of Software Systems

When upgrading your warehouse to the next level, you have options. A few of the warehouse software systems we recommend and work with include:

WCS – Warehouse Control Software PrecisionWare360

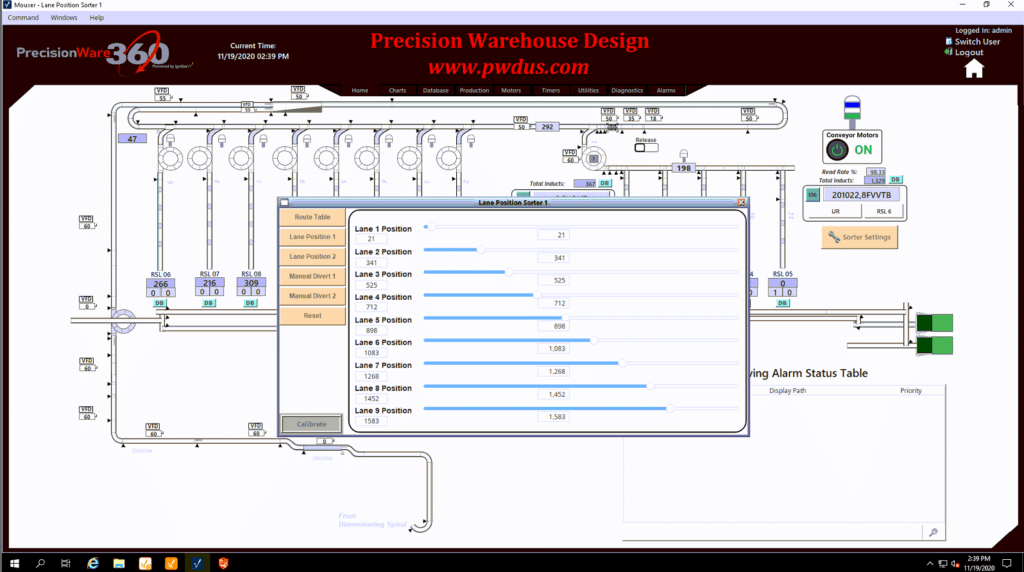

Warehouse Control Software, or WCS, helps warehouse operators to better control, monitor, and collect crucial data to make a more informed decision involving most warehouse systems and operations daily. This software is highly interactive, allowing for total control via a seamless dashboard to better manage day-to-day operations.

PLC – Programmable Logic Controllers

Programmable Logic Controllers, or PLCs, are a type of computer that receives data via various inputs and then transmits operating instructions based on the received data. This method allows warehouse operators to focus efforts elsewhere while the logic computer relays key information and instructions to other equipment within the facility, thereby keeping operations running smoothly.

HMI – Human Machine Interface

A human-machine interface, or HMI, includes a comprehensive but easy-to-use control unit, including a ‘control power’ operation, emergency stop, and indicators to let employees see which machines are running and their status at a glance. These devices pair well with a PLC to help save time and money, while also working with RFID for location tracking and permissions.

SCADA – Supervisory Control and Data Acquisition

At the highest level of warehouse management, supervisors must make split-second decisions to keep operations running smoothly. With such an expansive environment and many machines to consider, how?

A SCADA, or supervisory control and data acquisition system, provides clear visualization of all warehouse systems and statuses. From there, supervisors can plan maintenance accordingly, clear incidents, and optimize performance and machine availability.

WMS – Warehouse Management Systems

Warehouse Management Systems, or WMS, are warehouse software applications that allow operators to manage the day-to-day operations within the facility. This software, depending on the type you choose, because there are many to consider, allows users to handle receiving, stock location, inventory management, put-away tasks, order picking, order allocation, replenishment, packing, shipping, labor management, and so much more. The list goes on, with countless other benefits and uses of warehouse management systems that cannot be understated.

Pick to Light Solutions – IOT (Internet of Things) Devices

When dealing with any type of productivity shortcoming, it’s important to find and implement the proper solution in a timely manner. For many warehouses nationwide, this means investing in pick-to-light solutions, which are IoT devices capable of improving accuracy, increasing speed, offering real-time data capture, comprehensive labor reports, and reducing costs significantly over time.

Warehouse Software Systems Benefits and Applications

It’s common to take pause when it comes to investing in new services or software. After all, you’ve done everything manually — the old-school method — up until the point, why change?

There are numerous benefits to warehouse software systems, such as:

Inventory Visibility

When you work with countless materials and items, it’s easy to lose track of everyday goods along the line. But with software working overtime on your behalf, you can enjoy total inventory visibility with the utmost accuracy. Some software includes scanning, RFID, and location tracking methods to provide you with visual confirmation of each item.

Effective Workforce

Instead of hiring an expansive workforce to handle every aspect of the picking and packing process, you can allow warehouse software to manage the overhead and the bigger picture. Then, you can position the right amount of labor on a day-to-day basis.

Optimized Logistics and Processes

The right piece of warehouse software can help optimize your logistics and processes — all internal operations — by streamlining the inbound and outbound methods. By reducing or outright removing unnecessary activities, your workforce can instead focus on timely and accurate shipments instead.

Better Customer and Supplier Relations

With warehouse software in place, customers receive their orders in a timely manner thanks to improved order fulfillment and quicker deliveries overall. On the other hand, your suppliers will also enjoy reduced wait times, thereby improving their relationship with your warehouse and company as a whole.

Reduced Waste

If your warehouse works with various perishable goods, like food or beverages, ensuring products leave the warehouse on time can prove invaluable. A WMS system helps identify various items within the warehouse that require speedy picking and packing, thereby reducing waste and product loss, both of which affect your bottom line.

As you can see, there are numerous benefits to warehouse software systems that make investing in new technology a must for any warehouse in the country.

Let Us Design Your Warehouse System Today

At Precision Warehouse Design, we have full turnkey design capabilities to ensure you know how best to feed a sorting system appropriately, achieve the throughput rates you require, and manage your warehouse system utilizing state-of-the-art SCADA software and other solutions. Our software solutions can be implemented to monitor from most devices in the warehouse, or anywhere in the world!

Countless multi-billion dollar companies like FedEx, Nebraska Furniture Mart, Chewy.com, S&S Activewear, Mouser Electronics, RTIC, KGP, and others trust the engineering solutions and long-standing partnership with Precision Warehouse Design for today’s top warehouse software opportunities and advancements!

Regarding supply chain management, the best warehouse management software around comes from Precision Warehouse Design. Get in touch with us today and learn how we can streamline your warehouse operations!

let us design your system today

We have full turnkey design capabilities to show you how to feed a sort system properly, achieve the rates you desire, and manage the system with state of art SCADA software. Our SCADA software can be implemented to monitor from any device anywhere in the world!

See why Multi-Billion Dollar companies like FedEX, Nebraska Furniture Mart, Chewy.com, S&S Activewear, Mouser Electronics, RTIC, KGP, and multiple others trust the engineering and partnership of Precision Warehouse Design for their current and ongoing Conveyor Sortation and Design needs!