Store Inventory Efficiently with Pallet Racking Design and Installation Solutions

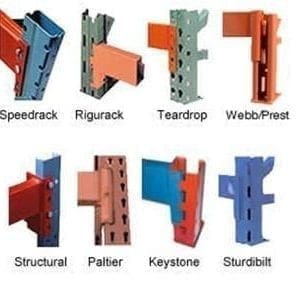

Pallet racks are the backbone of the warehouse, creating the framework upon which the inventory is stored. There are several types of pallet rack systems, each with their own benefits. Warehouse designers and managers select pallet rack systems based on various factors such as type and breadth of merchandise, number of articles per pallet, available space, and inventory turnover rate.

Of all the warehouse racking systems available, pallet racking systems are the most popular and versatile. Many warehouse managers prefer selective pallet racking systems because of the flexibility they offer within an existing warehouse storage system.

Your inventory and storage methods will dictate the best storage racking system for your warehouse environment. One of our pallet flow rack systems, a drive-in rack, or a push-back rack system may be the best solution for your facility. We are available to help you evaluate our pallet racking systems and help you choose the right warehouse racking system for your needs.

From Design, Deliver, Install, and Maintain we can turnkey your project for you. Yes, we can do the engineering Calc’s and Permitting as well. Our Sales and Engineering group have completed installations in 39 of the 50 states and 3 other countries so far!

There are many types of Pallet Racking Systems in today’s dynamic distribution centers. The appropriate system must be designed taking into consideration a few key elements. Let Precision Warehouse Design work with you to figure this out.

Get the Right Pallet Racking System for Your Needs

✔ Selective Pallet Racking Systems: Highest level of selectivity and most common design (Double Deep configurations as well).

✔ Pallet Flow Racking Systems: Low SKU counts, high number of pallets per SKU, high throughput requirement, highest level of space savings.

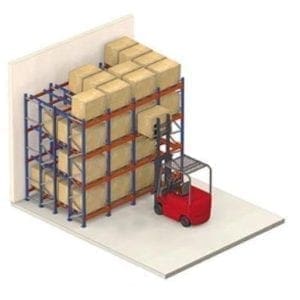

✔ Push Back Racking Systems: Medium to high number of pallets per SKU, great space savings

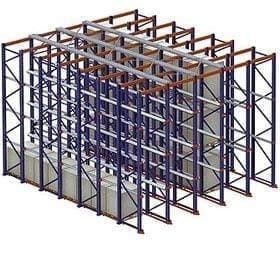

✔ Drive In/Drive Through Racking Systems: Low SKU counts, high number of pallets per SKU, high throughput requirement, highest level of space savings.

✔ Pick Module Racking Systems: Multi-level picking environment, usually associated with flow rack and case picking (or broken case picking).

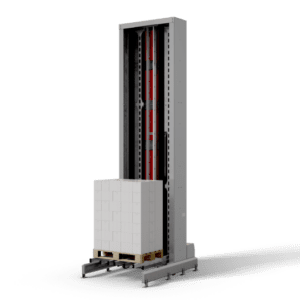

✔ Automated Systems: Mobile Aisle Systems, Automatic Retrieval Systems, Building Supported Systems

Let Us Design Your System Today

We have full turnkey design capabilities to show you how fit your storage system with the various types of storage in to your facility. We have extensive AutoCad skills and work with your operations staff to understand all the “Industrial Engineering” necessary to create a thoughtful and efficient design. Let one of our design specialist help you with your project!

We can go deeper as well and help design a software system for your inventory management. Companies like FedEX, Nebraska Furniture Mart, Chewy.com, S&S Activewear, Mouser Electronics, RTIC, KGP Logistics and many others trust the engineering and partnership of Precision Warehouse Design for their current and ongoing warehouse pallet rack projects!

Showing all 7 results