Warehouse Consulting Services

The Precision Warehouse Design warehousing and distribution consulting group has over 20 years of experience designing and improving distribution center facilities and operations. We offer material handling consulting services to small and medium-size businesses to help them deliver world-class service to ensure customer satisfaction and a least–cost operating position within their distribution operations.

Our Services include

- Master Planning

- Slotting Analysis

- Simulation

- Capacity Assessment

- Useful Life of Facility Assessment

- Project Management

- Proof of Concept

- Bid Specification Preparation

- FasTrak Design

Expanding On Our Services

Discover how each component of our suite of services is strategically crafted to elevate the efficiency of your warehouse operations.

The Role of Master Planning in Material Handling Consulting

Master planning is crucial for strategic warehouse design, acting as the framework that supports warehouse productivity operations and facilitates growth. A master plan includes a comprehensive evaluation of your current and future supply chain logistics needs, ensuring that your warehouse layout, technology, and processes are aligned with your business objectives. Armed with data, with our warehouse design consulting services we help you create a scalable and flexible operation that can adapt to market changes and business growth.

Exploring the Principles of Warehouse Slotting Analysis

Slotting analysis optimizes warehouse storage by strategically organizing inventory according to factors such as size, weight, and demand frequency. This enhances operational efficiency, reduces picking errors, and improves safety. By employing common warehouse slotting strategies—such as improving warehouse space utilization, assigning proper storage technologies by SKU velocity, minimizing parts handling, improving inventory accuracy, and enhancing worker ergonomics—we maximize the efficiency of your warehousing operations.

Leveraging Simulation in Material Handling Consulting

Simulation plays a pivotal role in warehouse consulting, allowing us to model and test different operational scenarios without disrupting your actual operations. Using simulation, we as warehouse consultants can anticipate potential challenges and devise solutions to complex logistical issues before they occur.

Facility Capacity and Useful Life Assessment in a Material Handling Consultation

Our assessments offer critical insights into how your current setup meets operational demands and what adjustments are necessary for future scalability. These evaluations inform your decision-making processes for expansion, redesign, or relocation in existing facility. This makes sure your infrastructure meets both present and future needs.

Proof of Concept

Proof of Concept (PoC) is a critical phase in our distribution center consulting services, designed to validate the feasibility of proposed warehouse management system solutions before full-scale implementation. This allows us to demonstrate the tangible benefits and potential ROI of our recommendations, ensuring that your investment in technology or process changes yields the desired outcomes. Through PoC, we mitigate risks by identifying any issues early, allowing for adjustments. This ensures its success in your unique operational context.

Bid Specification Preparation

Our bid specification preparation streamlines the procurement process. We provide a clear, detailed foundation for acquiring the equipment, technology, and services essential to your warehouse design. By crafting precise specifications, we help you articulate your needs effectively to vendors, ensuring accurate and comparable bids. This aligns purchases with your operational objectives and budget.

FasTrak Design

FasTrak Design stands as our accelerated warehouse design solution, enabling rapid development and deployment of warehouse layouts, systems, and processes. This service is ideal for businesses seeking swift improvements in their warehousing and distribution capabilities. Using the latest in design technologies and our extensive experience, FasTrak Design delivers optimized warehouse solutions that meet your immediate needs while providing the flexibility to scale and evolve with your business.

let us design your system today

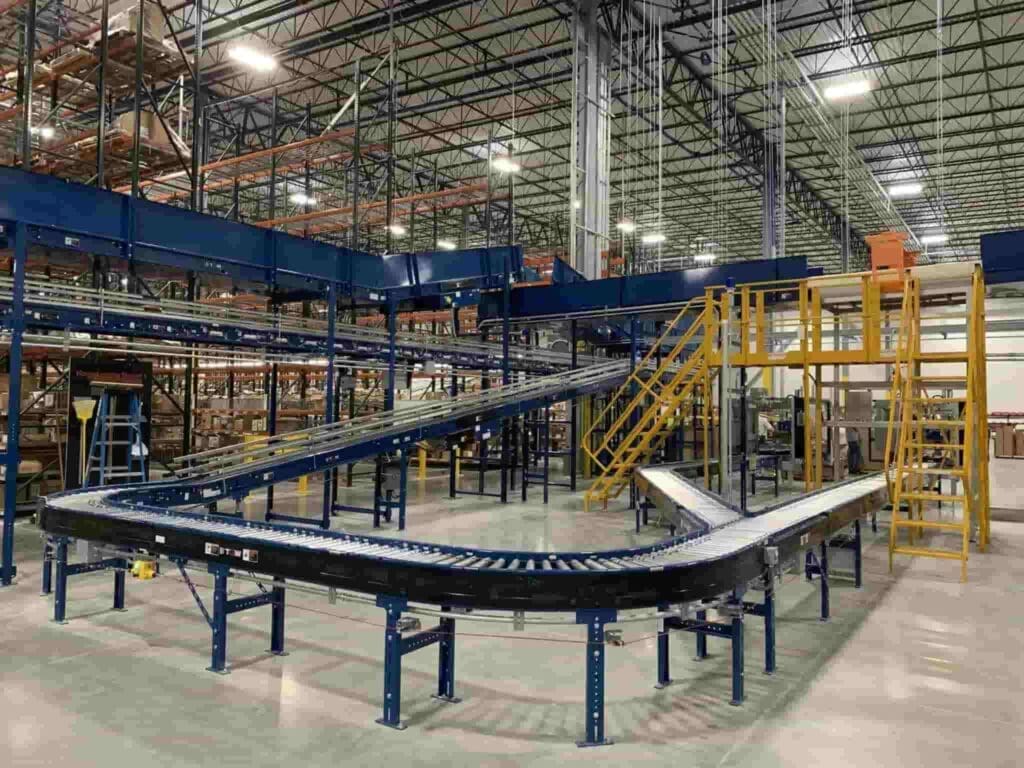

We have full turnkey design capabilities to show you how to feed a sort system properly, achieve the rates you desire, and manage the system with state of art SCADA software. Our SCADA software can be implemented to monitor from any device anywhere in the world!

See why Multi-Billion Dollar companies like FedEX, Nebraska Furniture Mart, Chewy.com, S&S Activewear, Mouser Electronics, RTIC, KGP, and multiple others trust the engineering and partnership of Precision Warehouse Design for their current and ongoing Conveyor Sortation and Design needs!

FAQs

What does a warehouse consultant do?

A warehouse consultant specializes in optimizing warehouse operations and design to enhance efficiency, productivity, and safety. They conduct thorough analyses of current practices, identify areas for improvement, and implement solutions tailored to a business’s unique needs. This can include redesigning warehouse layouts, integrating new technologies, and refining operational strategies to boost performance and reduce costs.

What does material handling systems include?

Material handling systems encompass a wide range of tools, devices, and vehicles used to transport, store, control, and protect goods within a warehouse or distribution center. This includes everything from forklifts, conveyors, and pallet jacks to automated storage and retrieval systems (AS/RS), robotics, and software solutions designed to streamline inventory management.

Why work with a warehouse design consultant?

Working with a warehouse design consultant offers numerous benefits, including access to expert knowledge and the latest industry trends. Consultants provide objective, data-driven advice on how to optimize your warehouse layout and operations for efficiency and scalability. They can help you navigate the complexities of warehouse management, from selecting the right material handling equipment to implementing cutting-edge technologies.

What are easy ways to automate a warehouse?

Automating a warehouse can start with simple, scalable solutions tailored to your specific needs. Consider implementing barcode scanning and RFID technologies for more efficient inventory tracking and management. Automated guided vehicles (AGVs) and robotic process automation (RPA) can streamline material movement and reduce manual tasks. Additionally, investing in warehouse management software (WMS) can provide real-time insights into operations, improve accuracy, and facilitate decision-making. Starting with one or two automation initiatives can pave the way for more comprehensive automation strategies as your operations grow.