Distribution

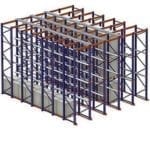

Storage of items in a distribution center is typically the largest of the space considerations.

As the fulfillment processes become more and more complex, and average order line counts trend smaller, it is essential that the storage media not compromise the impact of proliferating SKU counts, product seasonality, and productivity in the distribution environment. Lean cycle times and space for processing orders must be well planned for the optimal condition in SKU storage. This consideration covers everything from equipment size, FIFO/LIFO, configurations, flow, rolling stock, and aisle sizes to worker safety and work envelope.

The Right Storage

Design is Critical

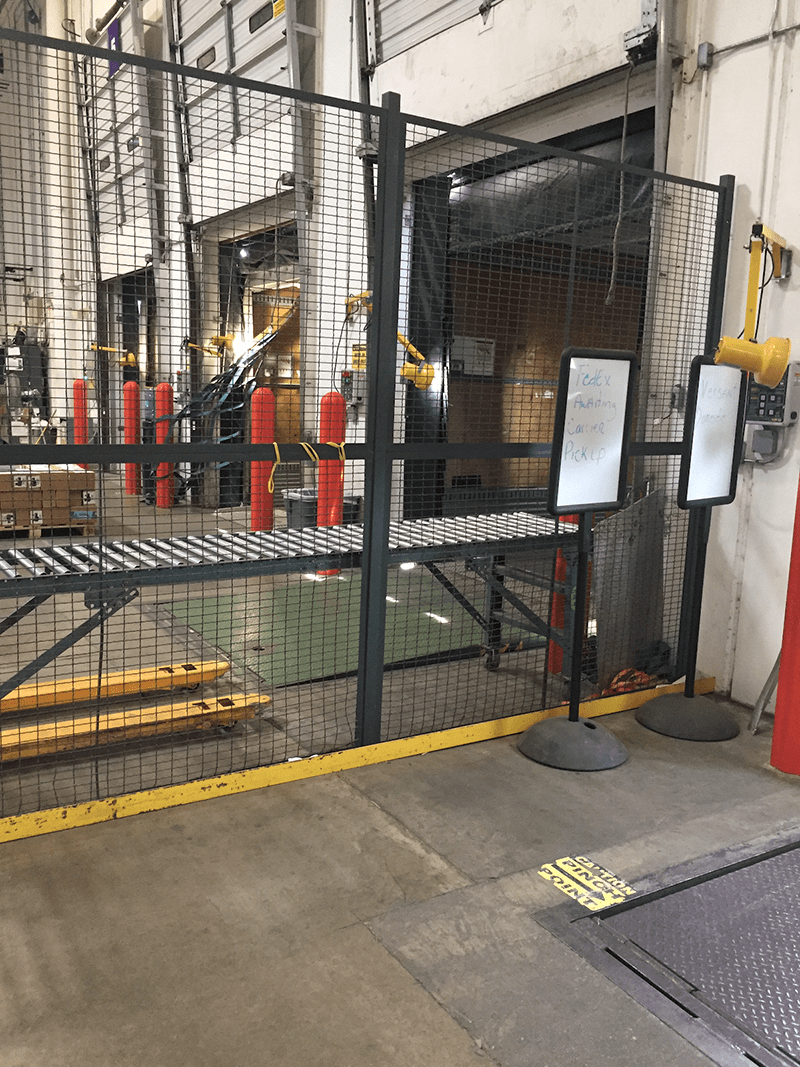

- – Receiving: From the arrival of materials to the distribution center through the decision where to place them comprises the receiving process. Good distribution practices start with good receiving processes. A good receiving strategy considers the physical properties of the items being processed, and the information required to process them into the facility. Additionally a good receiving process considers the space, staffing, and equipment required to execute a sound receiving strategy. Depending on the application, this area can be anything from a simple handheld terminal and workstation up to an automated in-motion scanning/sortation system.

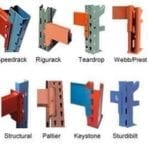

- – Order Picking: Order selecting in the world high speed distribution is ever-evolving in scale and technology. Poor equipment choices or implementation can be lethal when changes like item velocity or seasonality occur. Our approach is to do the math and let best practices select the order picking components. From simple shelving systems and rolling carts to complex order fulfillment solutions utilizing computer directed automated equipment, careful consideration and a fact-based approach ensure continuing productivity gains and system longevity.

- – Slotting: Item slotting can be the single largest contributing factor to distribution center productivity. Slotting strategies always consider four basic attributes for a given SKU. These attributes are: Product cube, Product popularity or velocity, Best fit storage media, and Environmental requirements This combination of attributes is called the SKU volumetric. Best practice distribution requires every SKU to have a predefined volumetric which supports the activity within the four walls of the distribution center

- – Replenishment: There is a requirement in some distribution centers to keep some products in a primary picking area(s) while maintaining the balance of the item in secondary and even tertiary locations. The process of moving items from these secondary locations to the primary picking area is a component of replenishment, coupled with receiving, that seeks to reduce product touches while maintaining inventory levels in the primary picking area.

- – Packing: Packing is defined as the activity that follows the picking or fulfillment activity in a distribution center. Good packing operations have well designed work envelopes coupled with good product flow concepts that ensure that packing does not become the constraint in the order fulfillment process. As order processing complexity increases with custom 3rd party labels and conformance labeling, the packing operation design is becoming more and more operation-critical. A good packing operation can include an ergonomic workstation design and/or the appropriate material handling equipment for large bulky items being handled.

- – Manifesting: Manifesting of orders is a broad category encompassing the activity between packing and shipping. It can include everything from relieving inventory, determining if a shipment is scheduled for a banned country; parcel carrier labeling, bills of lading, to triggering the customer invoice. Manifesting areas can be simple desktop scales and printers to in-motion scales, rate shipping software, and print and apply machines. Sorting: Today’s distribution center frequently has a requirement for sorting items prior to shipping. This can include support of routes, multiple stores, different shipment sizes such as parcel and less than truckload, and varying service levels such next day air, ground, etc. Sortation design must consider the current and anticipated requirements to prevent the solution from becoming obsolete. As this sorting grows in complexity, the sortation solution must grow with complexity.

- – Shipping: Shipping is the terminal activity in the distribution center. Shipping strategies considers the staging, loading, equipment and space required for successful movement of items out of the facility

- – Space Planning: Planning the space required for a successful distribution operation can include sharing a facility with other components of the operation such as manufacturing or quality control. Front planning minimizes constrained flows and crowding. Effective space planning should also consider and include sufficient staging areas.

- – Capacity Planning: Many of today’s products and entire operations are seasonal in nature. The challenge in the world of high speed distribution is determining the maximum capacity of a facility before the capacity constrains the operation. Part of this activity also addresses the useful life of the facility for the operation. When applicable site selection should account for expansion plans.

let us design your system today

We have full turnkey design capabilities to show you how to feed a sort system properly, achieve the rates you desire, and manage the system with state of art SCADA software. Our SCADA software can be implemented to monitor from any device anywhere in the world!

See why Multi-Billion Dollar companies like FedEX, Nebraska Furniture Mart, Chewy.com, S&S Activewear, Mouser Electronics, RTIC, KGP, and multiple others trust the engineering and partnership of Precision Warehouse Design for their current and ongoing Conveyor Sortation and Design needs!