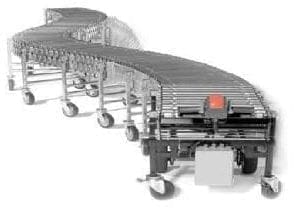

Flexible Conveyors: Versatile Material Handling Solutions

Flexible Conveyors, known for their adaptability and versatility, are integral to modern material handling systems. In this comprehensive guide, we will delve into the world of Flexible Conveyors, understanding their primary function, key features that set them apart, the myriad of benefits they bring to material handling processes, ideal use cases across industries, essential maintenance practices for prolonged lifespan, and the customization options offered by Precision Warehouse Design to tailor these conveyors to your unique needs.

Key Features of Flexible Conveyors

Flexible Conveyors possess several key features that make them invaluable in material handling:

- Expandable Design: They can be expanded and contracted, adapting to various space requirements.

- Versatile Roller Types: Available with different roller types to suit various materials.

- Portable: Easily movable, making them suitable for dynamic warehouse layouts.

Benefits and Advantages

The utilization of Flexible Conveyors offers numerous advantages in material handling:

- Space Efficiency: Their expandable design optimizes space usage, reducing the need for fixed conveyor systems.

- Cost-Effective: Versatility and portability translate to cost savings.

- Quick Setup: Rapid deployment, minimizing downtime during installation.

- Adaptability: Suited for handling a wide range of materials and products.

Ideal Use Cases

Flexible Conveyors find their applications across diverse industries and scenarios:

- E-commerce: Ideal for fast-paced e-commerce warehouses with ever-changing layouts.

- Distribution Centers: Effective in distribution centers where space optimization is crucial.

- Retail: Useful for temporary setups in retail spaces during sales or promotions.

Maintenance and Durability

To ensure the durability and longevity of Flexible Conveyors, regular maintenance is essential:

- Roller Inspection: Periodically inspect and replace worn or damaged rollers.

- Cleaning: Keep the conveyor free of debris to maintain smooth operation.

- Lubrication: Apply lubrication as recommended for moving parts.

Customization Options

Precision Warehouse Design offers customization options to tailor Flexible Conveyors to specific requirements:

- Length and Width: Adjust the dimensions to fit your workspace.

- Roller Type: Choose roller types suitable for your materials.

- Controls: Customize conveyor speed and controls for precise material handling.

- Accessories: Enhance functionality with accessories like side guides and safety guards.

Applications Across Industries

Flexible Conveyors in E-commerce

E-commerce warehouses benefit significantly from Flexible Conveyors due to their adaptability and portability. These conveyors efficiently handle the diverse range of products common in e-commerce operations.

Flexible Conveyors in Distribution Centers

Distribution centers often deal with fluctuating inventories and layouts. Flexible Conveyors provide an ideal solution, allowing rapid adjustments to accommodate changing needs.

Flexible Conveyors in Retail

Retail spaces frequently require temporary setups during sales or promotions. Flexible Conveyors can be quickly deployed and reconfigured as needed, enhancing retail operations.

Choose Precision Warehouse Design

Flexible Conveyors serve as versatile material handling solutions suitable for various industries and scenarios. Their key features, benefits, and customization options make them a valuable addition to any material handling setup. To explore how Precision Warehouse Design’s Flexible Conveyor solutions can enhance your operations, contact our experts today.

Explore more conveyor system types to optimize your material handling and production processes:

What are flexible conveyors?

Flexible conveyors are versatile material handling systems that consist of flexible and expandable conveyor belts. These conveyors can be easily adjusted and curved to suit different layouts and requirements, making them ideal for applications where flexibility and adaptability are crucial.

What are the benefits of using flexible conveyors?

Flexible conveyors offer several benefits, including:

Easy customization: They can be adjusted to different lengths, widths, and shapes to accommodate specific needs.

Space-saving: These conveyors can expand or contract as needed, making efficient use of available space.

Versatility: They can handle a wide range of products, from small packages to larger items.

Improved efficiency: Flexible conveyors allow for smooth and continuous material flow, reducing bottlenecks and increasing productivity.

Easy installation: They are usually modular and can be quickly assembled and integrated into existing systems.

Can flexible conveyors handle heavy loads?

Yes, flexible conveyors are designed to handle a wide range of loads, including both light and heavy items. The weight capacity of the conveyors may vary depending on the specific model and configuration. It is important to consult the product specifications or contact our team to determine the suitable load capacity for your application.

Are flexible conveyors easy to maintain?

Flexible conveyors are designed for ease of maintenance. They often feature modular components that can be quickly replaced or repaired if necessary. Regular cleaning and inspection of the conveyor belts and mechanisms can help ensure optimal performance and longevity. We provide maintenance guidelines and support to help you keep your flexible conveyors in excellent working condition.

Can flexible conveyors be integrated with other conveyor systems?

Yes, flexible conveyors can be integrated with other conveyor systems to create a seamless material handling solution. They can connect to fixed conveyors, incline or decline conveyors, and other specialized equipment. The flexible nature of these conveyors allows for easy adaptation to different layouts and configurations, making integration with existing systems relatively straightforward.