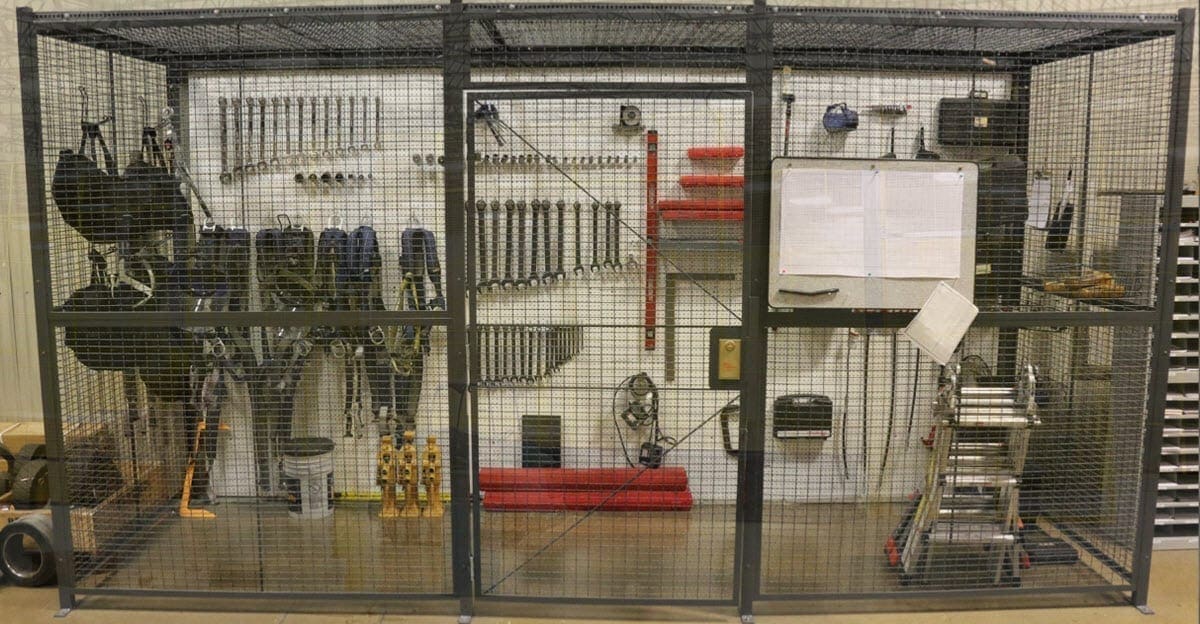

We can design the tool Crib to meet your specification.

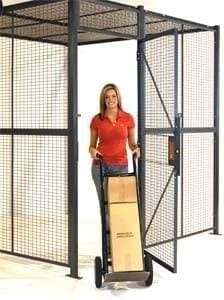

The modern warehouse requires costly and oftentimes dangerous tools and equipment to operate efficiently. In the right hands, these pieces of equipment are a boon to the company. In the wrong hands, they often prove unreliable, and expensive, and put everyone in the vicinity at risk. The solution? A high-strength tool crib designed for the ultimate storage of any and all equipment you require.

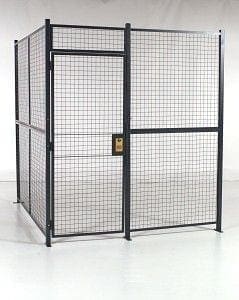

When it comes to securing equipment, we recommend opting for ceiling and wall panels to completely enclose your tool storage area. With tough sheet metal panels, sliding doors, or standard locking doors, and a tamper-resistant latch mechanism, safety on the warehouse floor becomes steadfast.

Here at Precision Warehouse Design, our number one goal, especially when it comes to tool cribs, is to ensure you’re satisfied with the overall design, aesthetic, and durability of the unit itself. That’s why we offer a variety of colors, finishes, and specifications to meet your ever-growing needs—both in a warehouse and manufacturing environment.

These tool cribs prove effective in all manner of work environments; from warehouses to pharmaceutical storage to law enforcement impound sites.

With high-quality tool cribs from Precision Warehouse Design, only allow those with clearance entry to your prized equipment. For more information, contact us today!

PANELS – Shall be 10gauge steel wire crimped and woven in to 2″ x 1″ opening rectangular mesh, securely welded into a frame of 1-1/4″ x 1-1/4″ x 1/8″ steel angle factory punched with 7/8″ x 7/16″ slotted holes to accept 3/8″ mounting hardware. Panels four to six feet wide shall have one 1/4″ x 3/4″ flat stiffener, wider panels receive two 1/4″ x 3/4″ stiffeners. All panels shall be fastened to posts with 3/8″ x 3″ plated bolts and nuts.

DOORS – Hinged shall be constructed of the same materials as the panels with two 1/4″ x 3/4″ horizontal stiffeners across the width, and two diagonal 1/4″ x 3/4″ stiffeners from center to the corner. Hinged doors shall be equipped with padlock lugs (cylinder lock optional), three 4″ x 4″ spun pin hinges, and pick plate/slam bar assembly.

DOORS – Sliding shall be constructed of the same materials as the panels with two 1/4″ x 3/4″ horizontal stiffeners across the width, and two vertical 1/4″ x 3/4″ stiffeners from center to top or bottom. Sliding doors shall be equipped with two 4 wheel trolley trucks, 1-7/8″ x 2-3/8″ door track, pad lock lugs (cylinder lock optional), and door keeper assembly.

POSTS – Shall be made of 2″ x 2″ x 14 gauge steel tubing. Base plates of 2″ x 7″ x 1/4″ steel flat with two 7/16″ round holes for anchoring, shall be welded to each tube. Posts are factory drilled with 1/2″ holes to accept hardware for mounting panels.

HARDWARE – Shall be 3/8″ standard thread grade two plated nuts and bolts. Floor anchors are 3/8″ wedge type-provided.

FINISH – Non-plated parts receive one coat of gray acrylic enamel. Touch up paint included with each shipment.