Ignition by Inductive Automation is a powerful warehouse automation software platform for industrial automation and control systems. It is designed to help businesses and organizations streamline their processes, increase efficiency, and improve outcomes by providing a comprehensive and cost-effective suite of tools to help with:

- Monitoring

- Controlling

- Analyzing warehouses and industrial facilities

- Any other operations that require robust and highly responsive instruments for logistics, analysis, and data management

Warehouse owners and facilities managers who want to stay competitive in modern markets are looking for ways to automate their operations, and converting to the Ignition platform can be a game-changer in this respect. It achieves this by integrating data from a wide range of sources, including PLCs, SCADA systems, MES systems, digital storage appliances, and all manner of other industrial software applications. Custom programming solutions can even allow it to integrate with your in-house applications and proprietary databases.

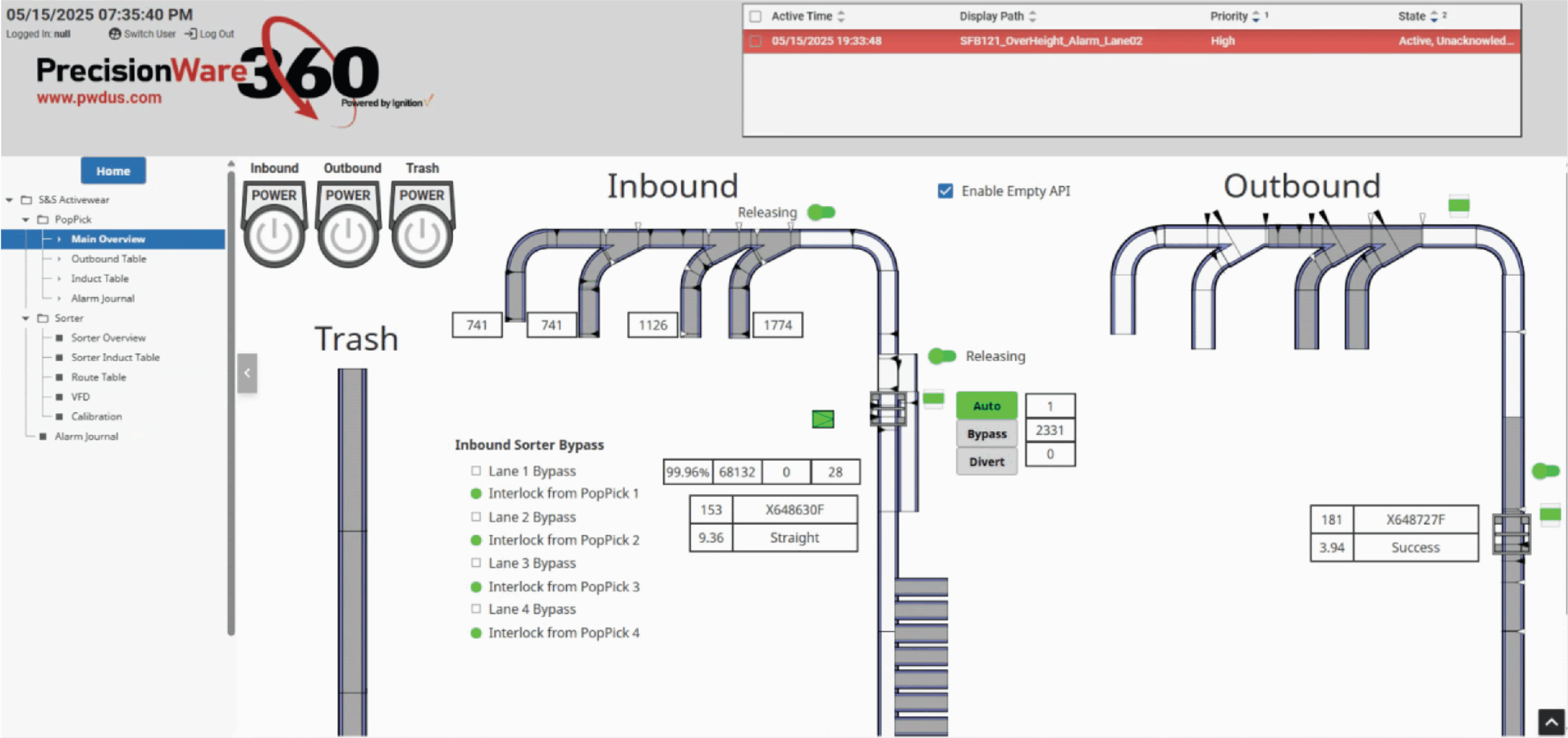

By integrating dozens or hundreds of data sources in an intelligent and highly functional way, Ignition allows users to easily monitor and control all aspects of their industrial operations from a single, coherent interface. This makes it easier to track inventory, manage workflows, and optimize processes for maximum efficiency.

What Is Ignition Software — and Why Does My Warehouse Need It?

One of the obvious key benefits of using Ignition software is the potential for significant cost savings. By automating routine tasks, businesses can reduce their reliance on manual labor, allow their employees to better manage their time and workflows, and improve productivity from end to end. All of this boosts your overall production rates and reduces customers’ returns and rejected deliveries — contributing significantly to your bottom line.

In the context of warehouse automation projects, Ignition can save money, reduce the need for tedious manual data entry tasks, and increase productivity at multiple phases of your operation. Put plainly, Ignition provides warehouse businesses with the tools they need to achieve maximum efficiency and profitability.

Another of the key advantages of using Ignition software is its near infinite scalability. Whether you’re operating a single, small warehouse or a large, complex distribution hub serving a dozen warehouses, Ignition can be easily scaled up or down to meet the exact needs of your operation. Ignition’s modular nature also makes it easy to add new features and functionality as needed, allowing businesses to customize the platform to suit the specific needs of their various departments and job roles.

In addition to this impressive scalability and cutting-edge tech, Ignition is also built on a solid philosophical foundation of open standards and technologies. This means it can easily integrate with virtually any other industrial system or device, making it simple to connect to existing industrial infrastructure and add new devices and systems as needed. There is also a great community of Ignition users and experts online to learn from and bounce ideas and issues off of.

When it comes to getting a great return on investment (ROI) for your decision to get on the automation bandwagon, Ignition software will be a key driver of cost savings and increased efficiency. By automating routine tasks and optimizing processes from end to end, Ignition-powered warehouses reduce their reliance on manual labor, improve throughput, and reduce the occurrence of errors. This can result in significant cost savings, increased production, and a competitive advantage in any marketplace.

Understanding Key Ignition Terms

Some key terms to understand with Ignition include:

- HMI. A “Human-Machine Interface” is a computer science term that broadly refers to the controls and systems through which you interact with computers and other machines. In this case, it refers to how we use computers to monitor equipment, inventory, personnel, and processes in a complex industrial operation. To that end, Ignition includes powerful HMI tools that allow users to create custom interfaces to meet the specific needs of their warehouse or industrial operations.

- MES. A “Manufacturing Execution System” is a type of software application used to manage and control a manufacturing process. Ignition includes MES tools that allow users to track and analyze manufacturing operations in real time.

- MQTT. This stands for “Message Queuing Telemetry Transport,” and it is a lightweight messaging protocol popular for machine-to-machine communication. Ignition includes built-in support for MQTT, making it easy to connect the various devices and systems that make up your operation.

- OPC-UA. “Open Platform Communications – Unified Architecture” is a set of open standards for industrial communication and data exchange platforms. Ignition includes built-in support for OPC-UA, which means it can easily integrate with a wide range of industrial devices and systems from any manufacturers or developers also complying with OPC-UA standards.

- SCADA. This stands for “Supervisory Control and Data Acquisition” and refers to a type of industrial control system used to monitor and control industrial processes. Ignition includes powerful SCADA tools that allow users to monitor and control complex industrial processes from a centralized location.

Precision Warehouse Design — A Reliable Partner for Your Ignition Implementation

At Precision Warehouse Design of Texas, we have extensive experience successfully implementing Ignition at warehouses and similar operations. We work closely with our clients to understand their unique needs so that we can design customized, end-to-end solutions that will meet the specific goals and requirements of each site.

Our team of software, automation, networking, and database experts has deep knowledge of the Ignition software platform, and we’re ready to help businesses like yours get converted to Ignition as efficiently as possible.

Contact us today to learn how to take the first step.