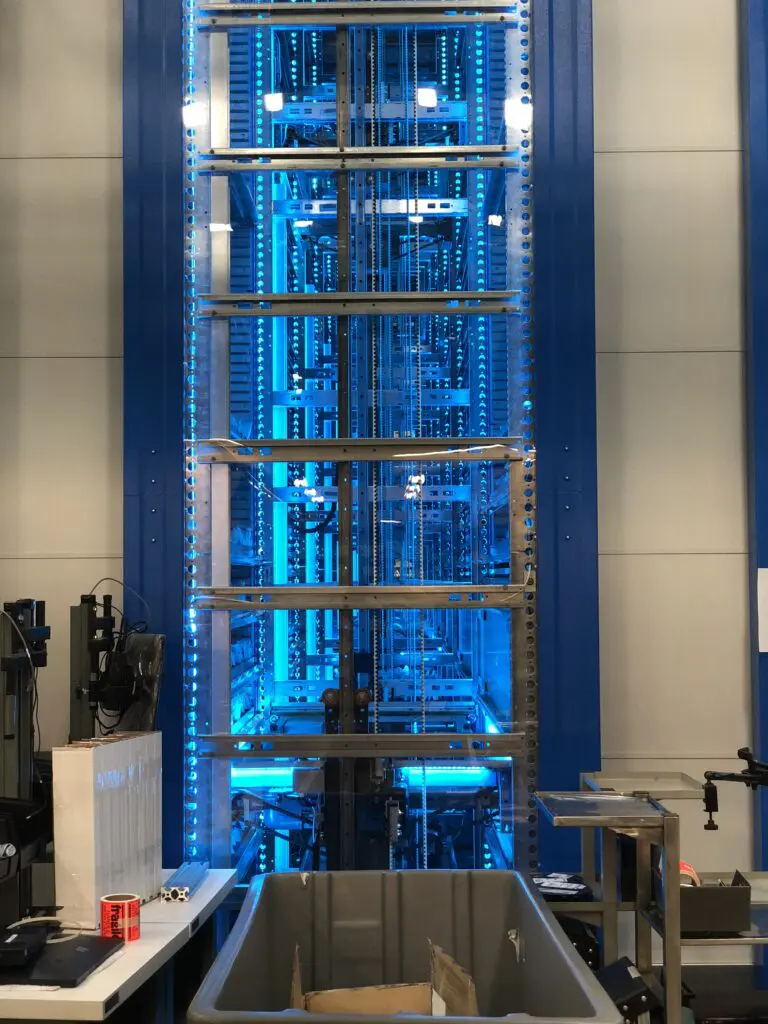

Vertical Lift Modules (VLMs) and carousels are automated vertical storage systems that deliver items directly to an operator at an ergonomic height. Instead of operators walking through aisles to find items, the system brings the requested item to the operator while also utilizing the vertical storage potential within a facility.

These consist of two columns of trays with an extractor/inserter in the center. When an item is requested, the extractor retrieves the tray containing the item and presents it to the operator at a workstation opening.

These operate similarly to a Ferris wheel, with carriers or shelves rotating vertically to bring requested items to an access opening.

Why are these vertical inventory systems crucial for modern warehouses?

They convert underutilized vertical space into accessible storage, often reducing the footprint needed for inventory by 80% or more.

By bringing goods directly to the picker, they eliminate walk and search time, dramatically increasing pick rates.

Light directed technology, controlled access and automated delivery minimize human error and provide enhanced security for valuable or sensitive items.

Presenting items at an ergonomic height reduces bending, stretching, and climbing, improving worker safety and comfort.

Our expertly integrated vertical inventory carousel and VLM solutions deliver measurable benefits that directly impact your operational efficiency and bottom line:

Recover up to 85% of floor space compared to traditional shelving, allowing for higher storage density or reallocation of space for other critical operations.

Operators can achieve significantly higher pick rates by eliminating travel time and presenting items directly, leading to faster order fulfillment.

Automated tracking and optional light directed technology within the system minimizes mispicks and lost inventory, providing real-time accuracy and reducing the need for manual cycle counts.

Controlled access points and secure internal storage provide an ideal solution for high-value components, tools, or regulated items.

Precision Warehouse Design approaches VLM and carousel storage with a comprehensive understanding of your inventory characteristics, throughput requirements, and operational goals. We recognize that selecting the right vertical parts carousel or VLM depends on a meticulous analysis of your SKU profiles, transaction volume, and existing facility layout.

Common challenges we solve with these systems include:

Maximizing storage within existing building footprints without costly expansion.

Dramatically increasing pick rates for small parts and components.

Improving security for high-value or sensitive inventory.

Enhancing ergonomics and reducing repetitive movements for operators.

Precision Warehouse Design partners with industry-leading manufacturers to deliver best-in-class vertical carousels and VLM solutions. Our tailored approach ensures we recommend the optimal system tailored to your specific needs and budget, rather than a limited product catalog.

Our trusted partners for VLM & Carousel Storage include:

We ensure that every VLM or carousel system we implement is seamlessly integrated with your existing Warehouse Management System (WMS), Enterprise Resource Planning (ERP), or Warehouse Control System (WCS). This connectivity provides real-time inventory updates, optimized task assignment, and comprehensive data for reporting and analytics.

Every VLM and carousel system we design is built for seamless integration into your existing or planned warehouse infrastructure. This ensures smooth data flow and synchronized operation with other automated or manual processes. We prioritize adherence to relevant industry safety standards (OSHA, ANSI) and best practices, designing solutions for optimal ergonomics and secure operation. Our experienced teams have a proven track record of successful implementations across the U.S. and Canada, serving diverse industries including manufacturing, automotive, electronics, and ecommerce.

Unlock significant space savings, boost picking efficiency, and enhance inventory accuracy with a custom-engineered VLM or vertical carousel storage solution from Precision Warehouse Design. Our expert engineers are ready to assess your facility and design a tailored system that transforms your small parts and inventory management.