Returns aren’t just inevitable, they’re increasing. Today, eCommerce return rates often exceed 20%, and inefficient returns processing eats into margins fast.

A high-performance returns fulfillment solution allows you to:

by automating sorting, labeling, and re-stocking.

by processing returns faster.

with quick refunds or exchanges.

through intelligent triage and product routing.

that slow down forward fulfillment.

We’ve designed systems for pharmaceutical returns that process up to 4,000 boxes per day, securely handling Class I–IV drugs from major retailers like supermarkets and pharmacies and systems that process over 25,000 cell phone returns per day. With extensive scanning and controlled sortation into secure processing areas, these systems balance compliance, speed, and accuracy.

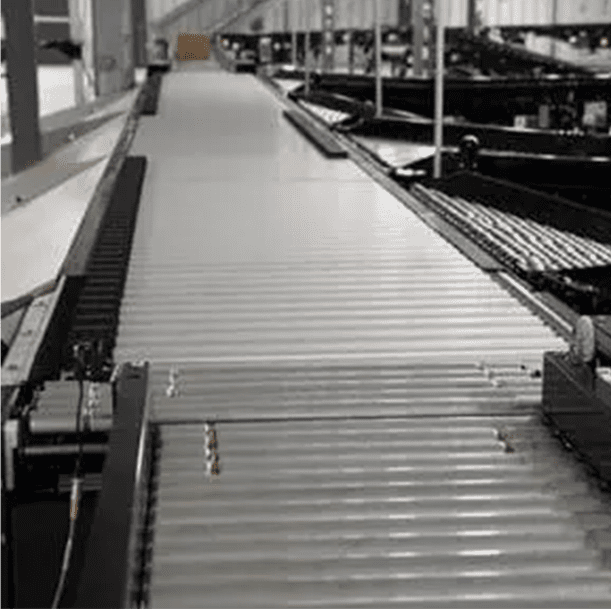

We offer engineered systems that support every phase of reverse logistics—from return receipt to restocking or dispositioning—customized for your operation.

Key Features:

Speed up check-in with barcode scanning, weighing, and image capture.

Automatically direct returned items to refurbish, resell, recycle, or restock paths.

Sync with your WMS or WCS to reintroduce inventory fast.

Route items immediately from returns to outbound shipping when applicable. No storage needed.

Apply custom business rules for refunding, restocking, or flagging damaged goods.

Our layout redesign and consulting for a high-volume eCommerce client reduced handling touches and cut processing time by nearly 20%. This level of design guidance is standard in every system we deliver.

Traditional returns processing can bog down warehouse space and staff. Our cross-docking solutions eliminate unnecessary touches by redirecting returns to the next destination—be it another customer, vendor, or processing center—without storage delays.

This is especially powerful for:

We approach every project as engineers and systems integrators, not just equipment providers. That means we don’t just install hardware; we design full-scale, end-to-end systems that work with your existing technology stack.

Whether you need a small automation cell or a full returns processing zone, Precision Warehouse Design delivers:

We bridge the gap between your warehouse floor and your IT infrastructure, ensuring your returns fulfillment is not only automated but also intelligent and connected.

We can solve these problems for a wide range of facilities across various industries, and we can solve them for you, too.

Returns fulfillment, also known as reverse logistics or returns management, is the process of handling products customers send back, from the moment a return is initiated until the item is either restocked, refurbished, or disposed of. It’s crucial for e-commerce because a seamless and efficient returns process builds customer trust and loyalty, directly impacting repeat purchases and your brand’s reputation, while also allowing businesses to recover maximum value from returned goods.

An efficient returns process significantly benefits your business by boosting customer satisfaction and loyalty, leading to repeat purchases and positive word-of-mouth. Furthermore, it allows for quicker processing of returned goods, enabling faster restocking or disposition, which minimizes losses and maximizes value recovery from inventory.

For high-volume e-commerce returns, businesses often leverage a combination of strategic approaches and technological solutions. Key solutions include implementing specialized Returns Management Systems (RMS) that automate everything from customer initiation of returns and label generation to refund processing and inventory updates. Many businesses also employ warehouse automation like robotic sorting systems and automated guided vehicles (AGVs) at dedicated return stations to quickly inspect, categorize, and direct returned items to their next destination (e.g., restock, repair, liquidation). Some choose to partner with a 3PL that specializes in reverse logistics so they can offload the entire returns process.

Cross-docking significantly improves returns handling within reverse logistics by minimizing storage time; returned items are quickly sorted and transferred directly to their next destination (e.g., refurbishment, liquidation, or back to a vendor) rather than being put into warehouse storage. This rapid movement reduces holding costs, frees up warehouse space, and accelerates the entire returns cycle, ultimately maximizing value recovery from returned goods.

Whether you’re building a new fulfillment center, retrofitting an existing warehouse, or expanding your returns capabilities, Precision Warehouse Design can help you implement an automated solution that scales with your business.