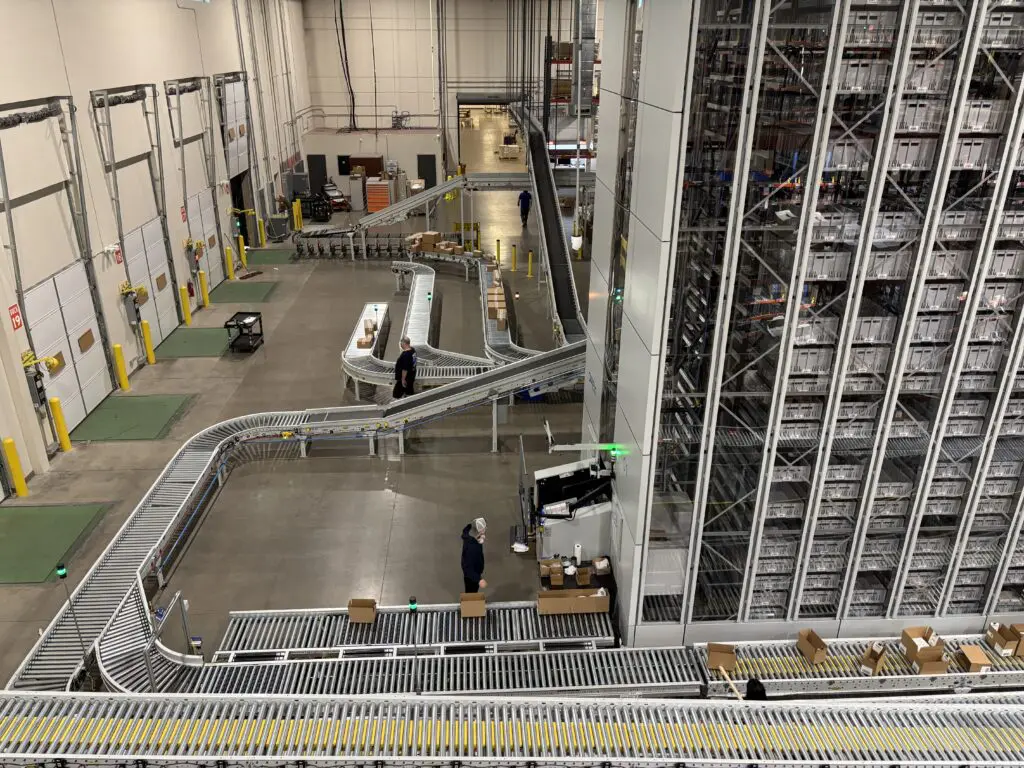

A pick module system is a high-density, multi-level storage solution that supports faster order picking through smart product positioning and integrated material flow. Items are strategically slotted throughout the system, allowing pickers to fulfill orders with fewer steps and less travel time.

Pick modules are often integrated with technologies such as:

These systems can be single-level or multi-tier, depending on your volume and SKU count. Whether fulfilling ecommerce orders or managing retail replenishment, pick modules deliver fast, accurate, and scalable performance.

Choosing the right picking system for your warehouse can lead to significant performance gains. A well-designed pick module improves every step of the order fulfillment process:

Whether you are replacing static shelving or expanding into a multi-tier structure, a modular system brings efficiency, safety, and adaptability to your operation.

Warehouse leaders often struggle with:

Our engineering team addresses these issues through careful layout planning, material flow analysis, and technology integration. Every pick module system we build is designed to eliminate operational friction and drive higher performance.

Precision Warehouse Design integrates modern picking system warehouse technologies into every solution. Depending on your throughput and fulfillment model, we may recommend:

for fast-moving SKUs and visual accuracy

for hands-free operation and complex orders

to ensure real-time verification and traceability

for continuous product flow between zones

for dynamic replenishment

to sync inventory and optimize task assignment

Our team works across multiple platforms and vendor ecosystems to create solutions that fit your workflow and budget.

A complete pick module system typically includes:

for high-volume case or piece picking

for bulk reserve or replenishment stock

to maximize vertical space

for seamless order movement

to ensure OSHA compliance

designed for ergonomic access

We customize the structure based on your SKU velocity, order profiles, facility height, and safety requirements. Our team also manages permitting, code compliance, and third-party contractor coordination.

We work with a range of leading vendors to source and implement high-quality picking technology and equipment, common solutions for pick module may include:

Our independence means we recommend the right solution, not just one brand.

If your facility is dealing with high labor costs, slow order turnaround, or poor picking accuracy, a pick module system can be a transformative investment. The engineers at Precision Warehouse Design will evaluate your current layout, order mix, and growth forecasts to develop a solution built for performance and longevity.

From concept to installation, we manage every step of the process, ensuring your system is compliant, efficient, and ready to scale.

Let Precision Warehouse Designs show you how a custom-designed pick module can revolutionize your operations. Contact us to increase picking efficiency and maximize performance.