As an authorized distributor and certified systems integrator, Precision Warehouse Design combines Regal Rexnord’s proven technology with our mechanical engineering expertise to deliver turnkey conveyor and sortation systems that optimize your fulfillment, manufacturing, or distribution operations.

Our partnership delivers:

by experienced mechanical engineers

with existing conveyor infrastructure

from design through commissioning and maintenance

including ModSort and automated sortation systems

backed by both Regal Rexnord and Precision Warehouse Design

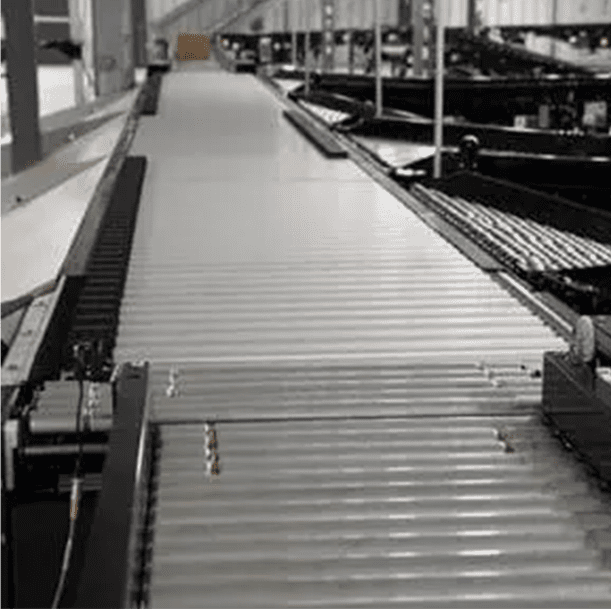

The ModSort divert and transfer module represents the latest innovation from Regal Rexnord—a game-changing sortation solution that’s transforming how warehouses and fulfillment centers handle everything from business cards to boxes, polybags to totes.

ModSort technology handles what traditional sortation systems can’t. This multi-directional sort machine integrates seamlessly into your existing system with controller cards and 24V DC roller technology, eliminating the complexity and energy waste of conventional diverters.

ModSort Conveyor Capabilities:

Business cards to 50-pound boxes (custom configurations available for heavier loads)

180-230 feet per minute with sort rates up to 40-60 items per minute

Polybags, small packages, boxes, and totes without gaps or transfer issues

Customized to your exact operational requirements

ModSort systems deliver energy savings of 50-60% compared to traditional conveyors when integrated with motorized roller-based systems. With low voltage operation (24VDC) and run-on-demand technology, you’re not just moving product more efficiently—you’re dramatically reducing operational costs.

Technical Advantages:

Beyond ModSort, Precision Warehouse Design installs and integrates the full range of Regal Rexnord conveyor technologies to create complete material handling solutions:

Rexnord Curve Systems

Zero tangent 90 and 180-degree curves with the tightest inner radius in the industry, maintaining product orientation throughout the turn

Conveyor Components

Chains, sprockets, modular plastic belts, mounted bearings, and complete conveyor assemblies

Automation Solutions

Palletizers, robotics, accumulation systems, and complete food and beverage conveyor systems

Drive & Motion Control

Variable speed motors, gear motors, AC & DC drives optimized for conveying applications

The challenge isn’t just purchasing a ModSort system—it’s integrating it effectively into your current sortation scheme. Our mechanical engineering team handles:

with factory certification

in material handling systems

for complex integrations

from design through installation and support

with Fortune 500 companies and growing operations

Pricing for ModSort divert beds ranges from $13,000 to $20,000 per station. The complete project cost depends on integration complexity, controls requirements, and how the ModSort fits into your current sortation design. Our mechanical engineering team provides detailed quotes that account for your complete system requirements—no surprises, just logical solutions.

Get a precise quote for your application. Every operation is unique, and we tailor each ModSort integration to maximize your specific return on investment.

ModSort systems are available in eight sizes to accommodate different product dimensions, flow rates, and facility layouts. Our team helps you select the optimal configuration based on:

Upgrade your operation with a fully integrated ModSort conveyor or Regal Rexnord system engineered for your facility’s exact needs. Schedule your consultation today and see how Precision Warehouse Design delivers smarter, more efficient automation.